Re-Grooving Tube Hole in Tube Sheet

Products

- Fittings

- Instrumentation Valves

- Manifold Valves

- Double Block And Bleed Valves

- Industrial Valves

- Quick Release Couplings

- Air Headers

- Condensate Pots

- Flanges

- Flange To Tube Adaptors

- Thermowells

- Fastners

- Pipe Clamps

- Flush Rings

- Hose Fittings

- Heat Exchanger Tube Plugs

- Heat Exchanger Ferrule Inserts

- Vent Plugs

- Header Unf Plugs

- Grease Fittings

- Pipes And Tubes

- Coils, Sheets & Plates

- Angle, Channels & Bars

- Tube Sheets

- Heavy Machined Components

-

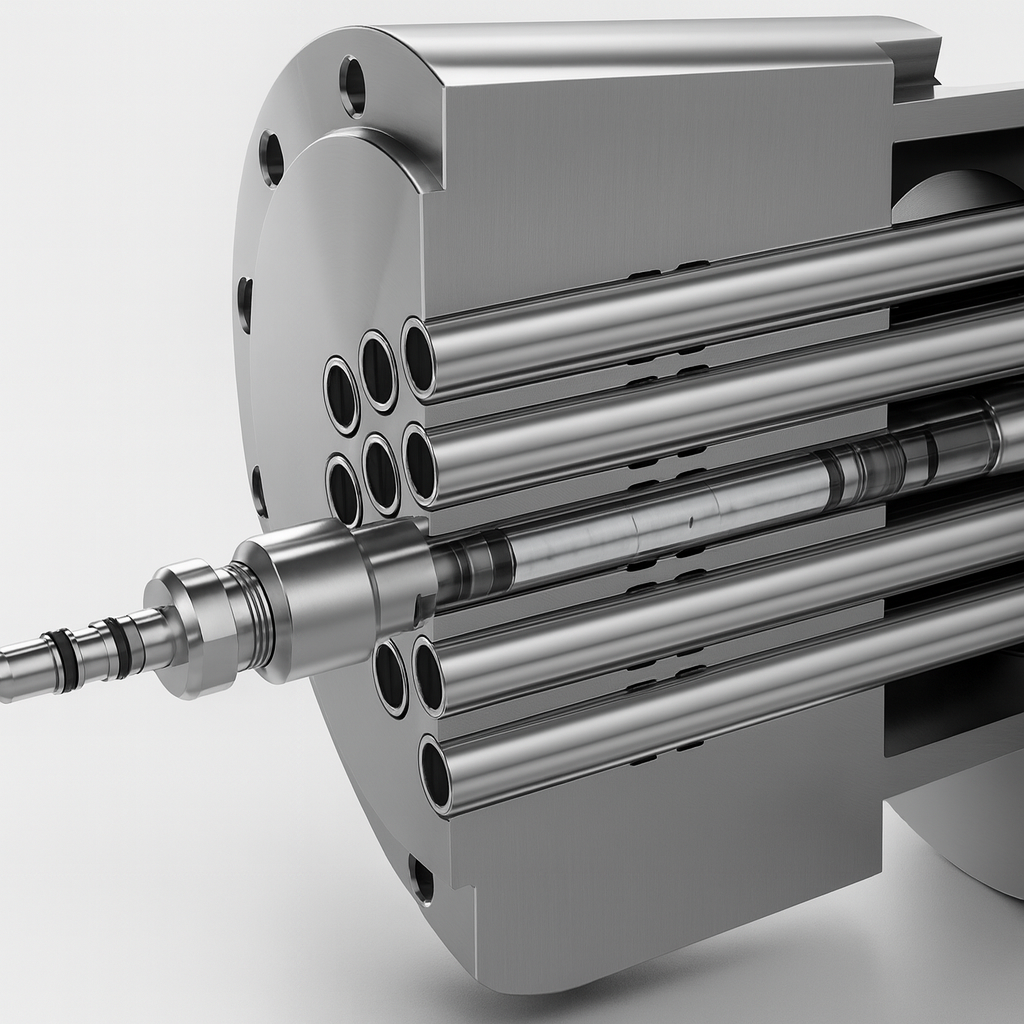

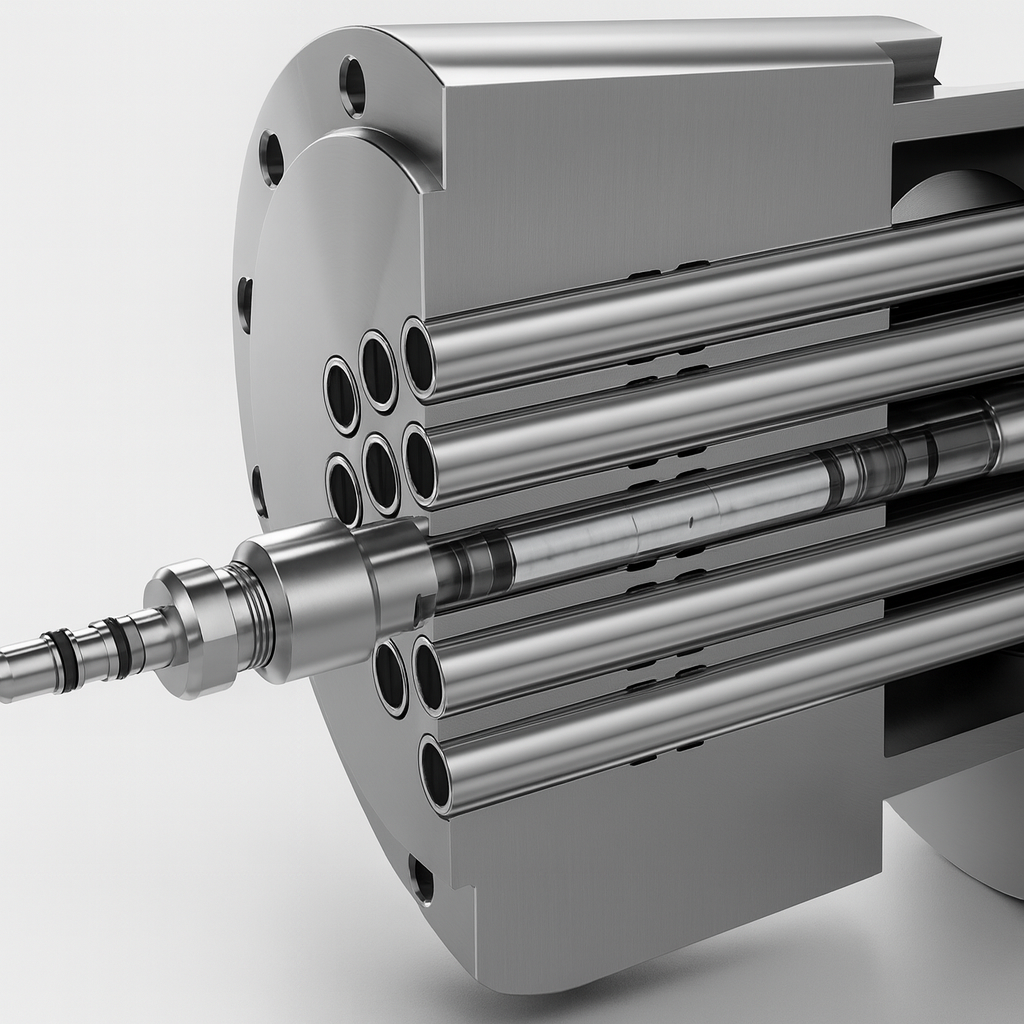

Re-Grooving Tube Hole in Tube Sheet

-

Tube Installation Tools

Re-Grooving Tube Hole in Tube Sheet

Re-grooving tube holes in a tube sheet is a process used to repair damaged or worn tube holes in a heat exchanger tube sheet. Over time, the tube holes in the tube sheet can become damaged or worn due to the constant expansion and contraction of the tubes. Re-grooving involves cutting new grooves or channels in the tube sheet to accommodate new tubes. Re-grooving tube holes in a tube sheet is a complex process that requires specialized equipment and experienced technicians.- Inspection: The tube sheet is inspected to identify any damaged or worn tube holes that need to be re-grooved.

- Grooving: The damaged or worn tube holes are re-grooved using specialized equipment, such as a tube sheet grooving machine. The grooves are cut to the correct depth and spacing to accommodate the new tubes.

- Tube Installation: The new tubes are then installed into the re-grooved tube holes, typically using a tube expander to ensure a secure fit between the tubes and the tube sheet.

- Testing: The heat exchanger is then tested to ensure that the new tubes are properly installed and there are no leaks or other issues.