Pop A Plug Installation

Products

- Fittings

- Instrumentation Valves

- Manifold Valves

- Double Block And Bleed Valves

- Industrial Valves

- Quick Release Couplings

- Air Headers

- Condensate Pots

- Flanges

- Flange To Tube Adaptors

- Thermowells

- Fastners

- Pipe Clamps

- Flush Rings

- Hose Fittings

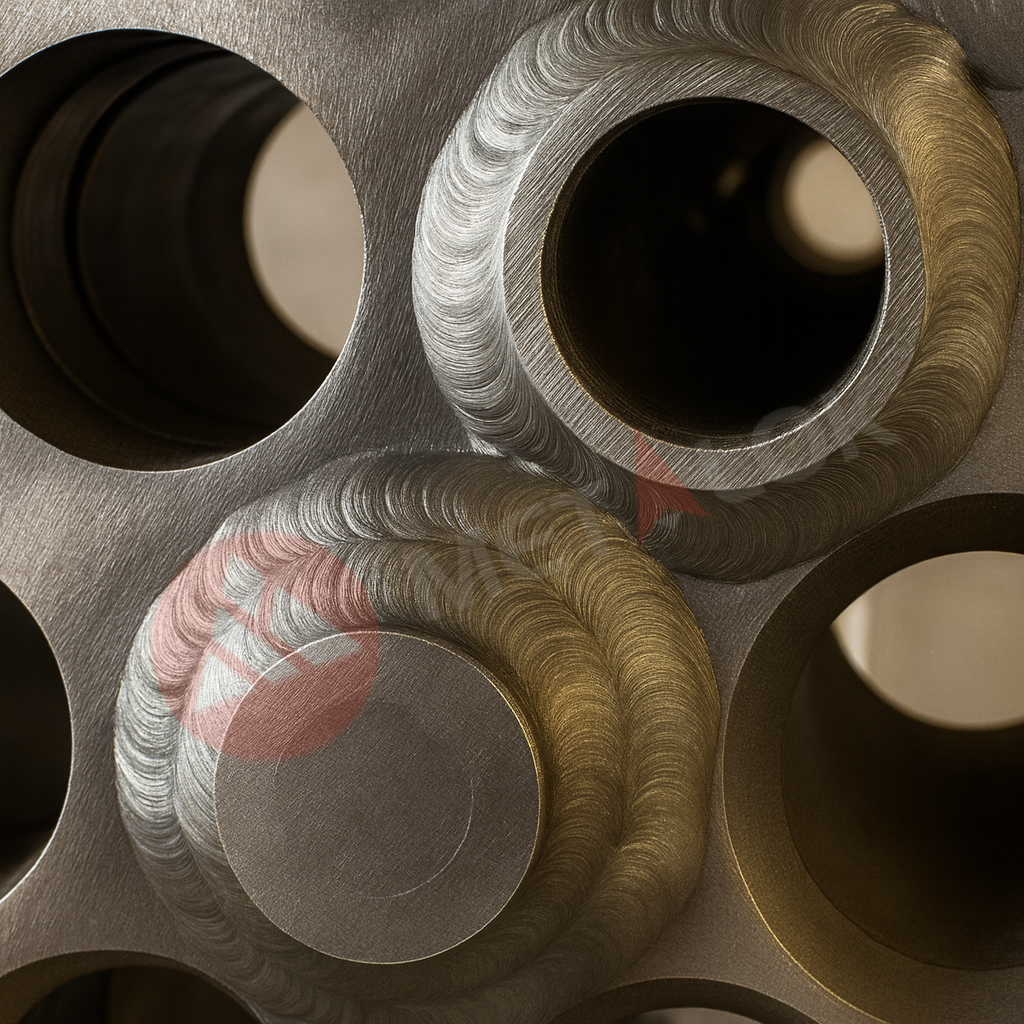

- Heat Exchanger Tube Plugs

- Heat Exchanger Ferrule Inserts

- Vent Plugs

- Header Unf Plugs

- Grease Fittings

- Pipes And Tubes

- Coils, Sheets & Plates

- Angle, Channels & Bars

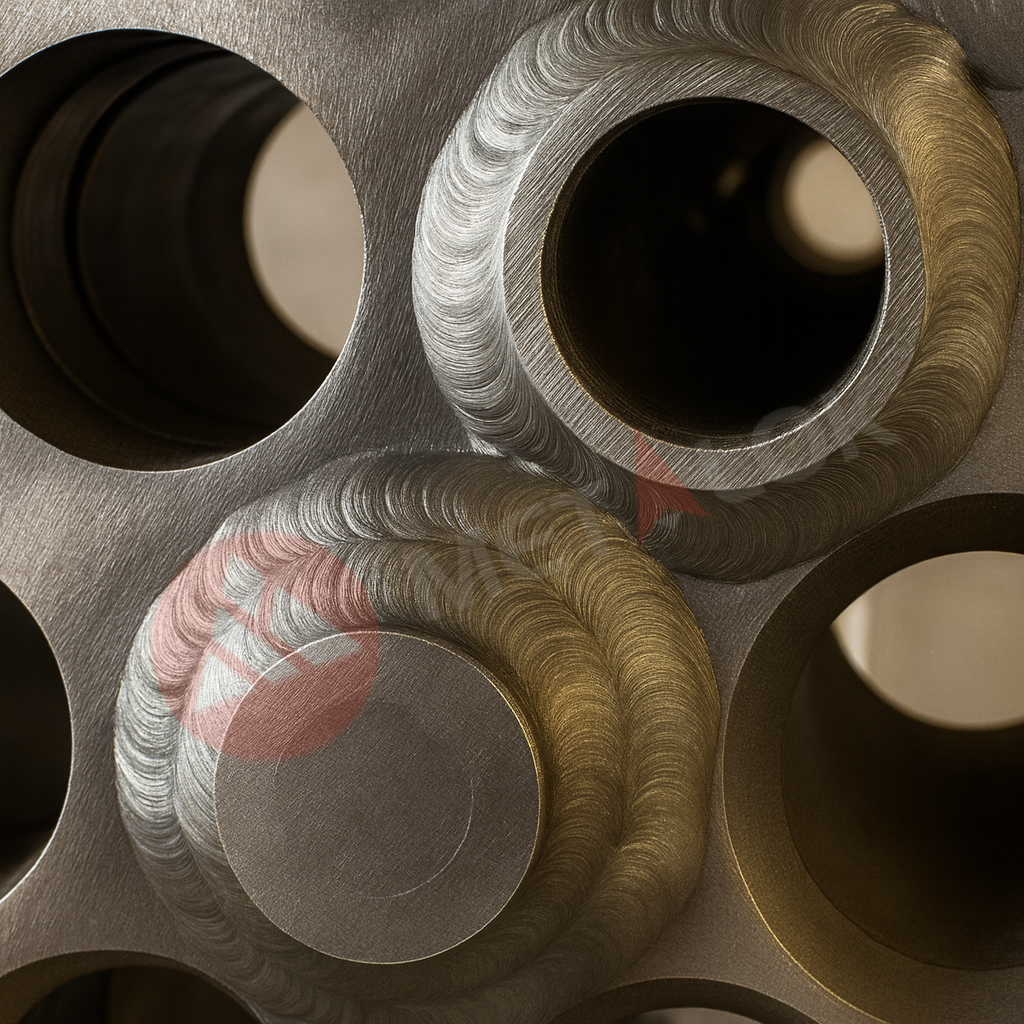

- Tube Sheets

- Heavy Machined Components

-

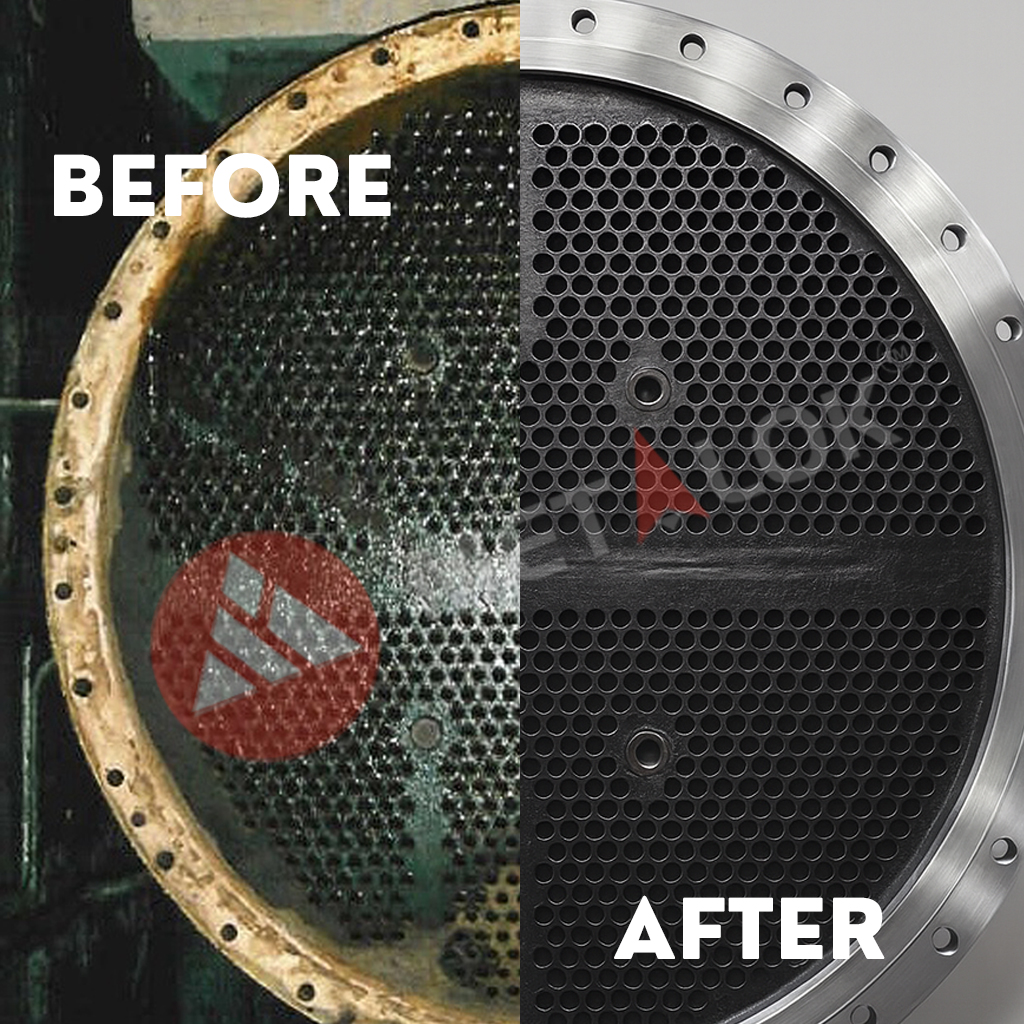

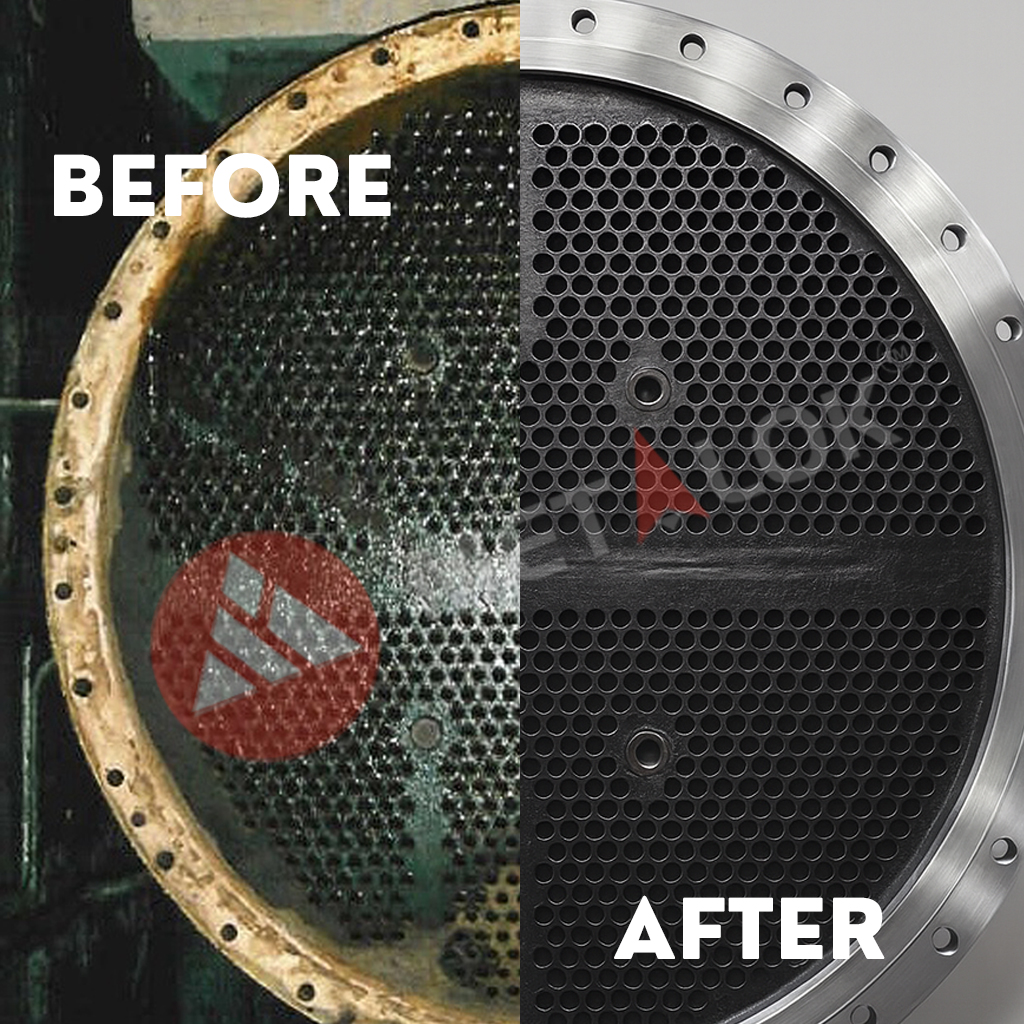

Cleaning

-

Cleaning

-

Installation

-

Installation

-

Installation

Pop A Plug Installation

Pop-A-Plug systems offer a safe, effective, and highly reliable solution for sealing heat exchanger tube and tube sheet leaks. These mechanical fit plugs are engineered to withstand extreme thermal cycling and provide a helium-tight seal, ensuring long-term performance and system integrity.

Metalok Industries employs certified and experienced technicians equipped with specialized tools and precision instruments to perform Pop-A-Plug installation and removal with utmost accuracy and safety. Our team follows strict technical standards to guarantee leak-free, permanent sealing without damaging the tube or tube sheet.

It is crucial that installation and removal of Pop-A-Plugs be carried out only by qualified Metalok technicians with proper certification and training. This ensures full compliance with safety protocols and reliable performance under both low-pressure conditions (up to 68.9 BarG) and high-pressure applications (up to 483 BarG) in heat exchangers and condensers.

- Ensure the heat exchanger is fully depressurized, isolated, and drained before beginning work.

- Confirm all safety permits are approved and wear proper PPE (helmet, gloves, face shield, etc.).

- Identify and mark all leaking or damaged tubes requiring plug installation.

- Clean the tube ID thoroughly using a wire brush or abrasive tool to remove any corrosion or debris.

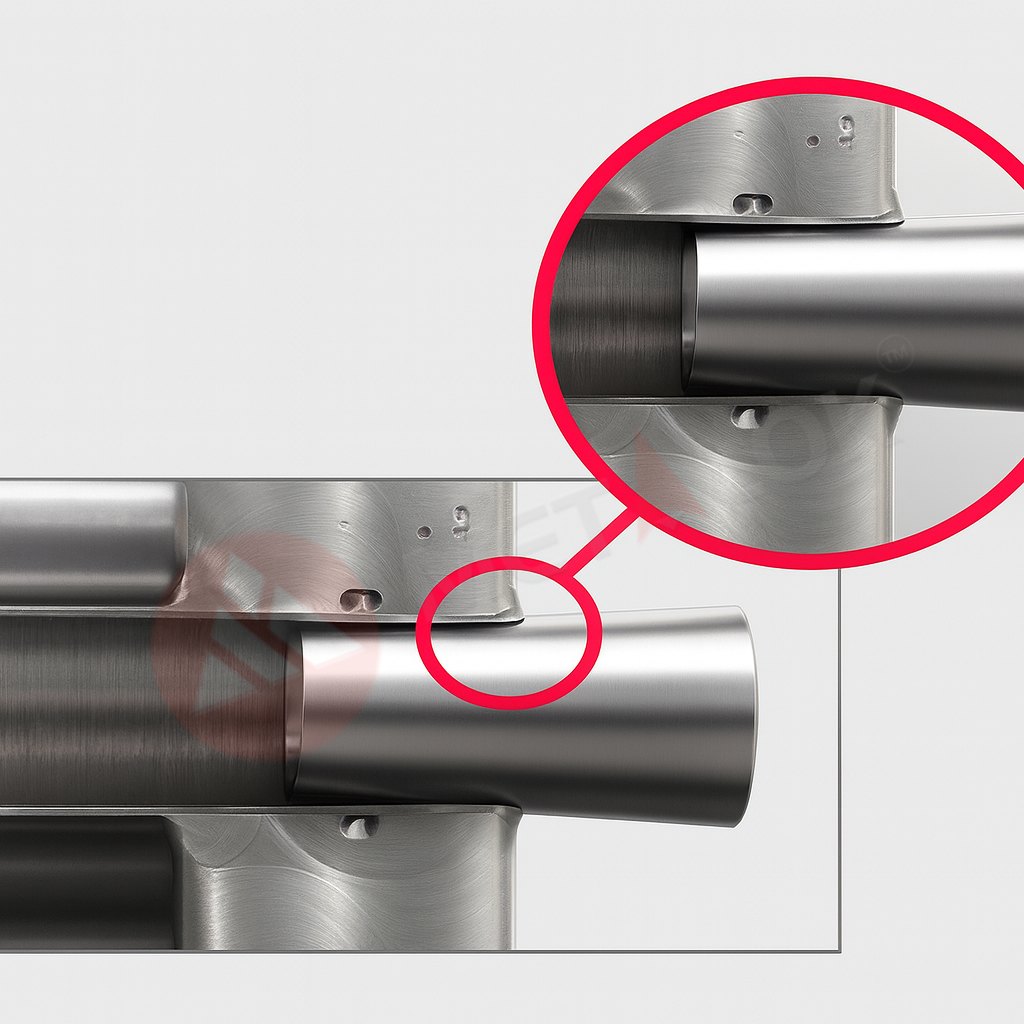

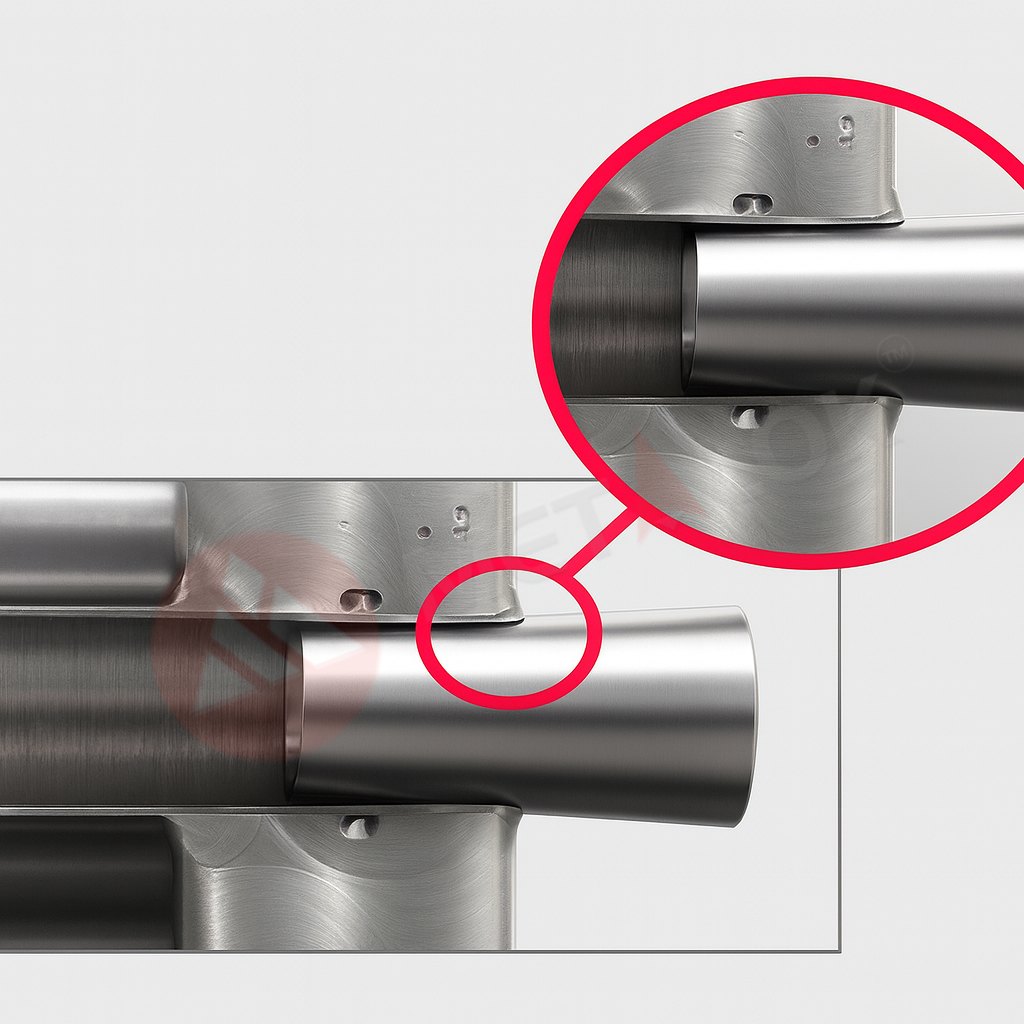

- Inspect the tube and tube sheet for damage, ovality, or pitting before proceeding.

- Select the correct Pop-A-Plug size and material compatible with the tube’s inner diameter and service conditions.

- Assemble the Pop-A-Plug installation tool as per manufacturer instructions, ensuring all components are clean and properly aligned.

- Insert the Pop-A-Plug assembly into the tube and activate the tool to expand the plug, creating a tight, leak-proof mechanical seal.

- Remove the installation tool carefully and verify the plug is properly seated and flush with the tube sheet.

- Perform a pressure or helium leak test to confirm a proper seal, then document plug locations and test results.