Heat Exchanger Retubing

Products

- Fittings

- Instrumentation Valves

- Manifold Valves

- Double Block And Bleed Valves

- Industrial Valves

- Quick Release Couplings

- Air Headers

- Condensate Pots

- Flanges

- Flange To Tube Adaptors

- Thermowells

- Fastners

- Pipe Clamps

- Flush Rings

- Hose Fittings

- Heat Exchanger Tube Plugs

- Heat Exchanger Ferrule Inserts

- Vent Plugs

- Header Unf Plugs

- Grease Fittings

- Pipes And Tubes

- Coils, Sheets & Plates

- Angle, Channels & Bars

- Tube Sheets

- Heavy Machined Components

-

Heat Exchanger Retubing

Heat Exchanger Retubing

Metalok Industries Arabia provides comprehensive Heat Exchanger Retubing Services designed to restore efficiency, performance, and reliability of industrial heat exchangers operating in demanding environments. Our expertise covers complete retubing, partial retubing, and tube sheet refurbishment for all types of exchangers — shell & tube, finned tube, air cooler, and condenser units.

We utilize high-quality materials such as stainless steel, carbon steel, copper-nickel, titanium, and other alloys to match your process requirements. Every retubing project is carried out by certified technicians using advanced equipment to ensure precise tube removal, tube-to-tube sheet expansion, welding, and hydrostatic testing that meet international standards such as ASME and TEMA.

Our retubing process includes thorough inspection, cleaning, non-destructive testing (NDT), and leak detection to ensure long service life and optimal thermal performance. We focus on minimizing downtime through onsite execution, quick turnaround, and safety-driven procedures, making Metalok Industries a trusted partner across the oil & gas, petrochemical, and power generation sectors.

With a dedicated service team based in Saudi Arabia, Metalok Industries delivers end-to-end retubing solutions — from assessment and material supply to installation and final pressure testing — ensuring your heat exchangers operate efficiently and reliably under all process conditions.

- Inspection & Assessment: Evaluate the existing tubes for corrosion, leakage, erosion, or mechanical damage.

- Material Selection: Choose suitable tube materials (SS, CS, Cu-Ni, Titanium, etc.) as per process and design standards.

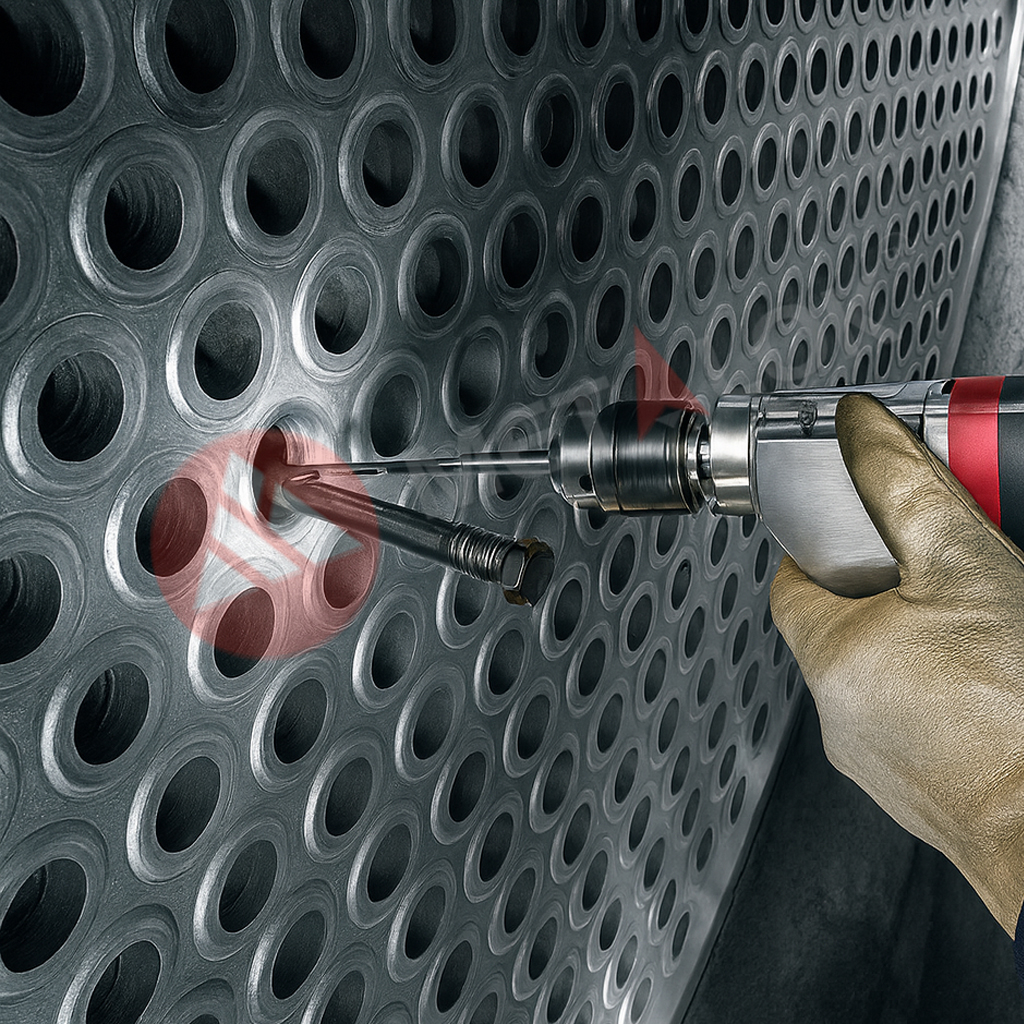

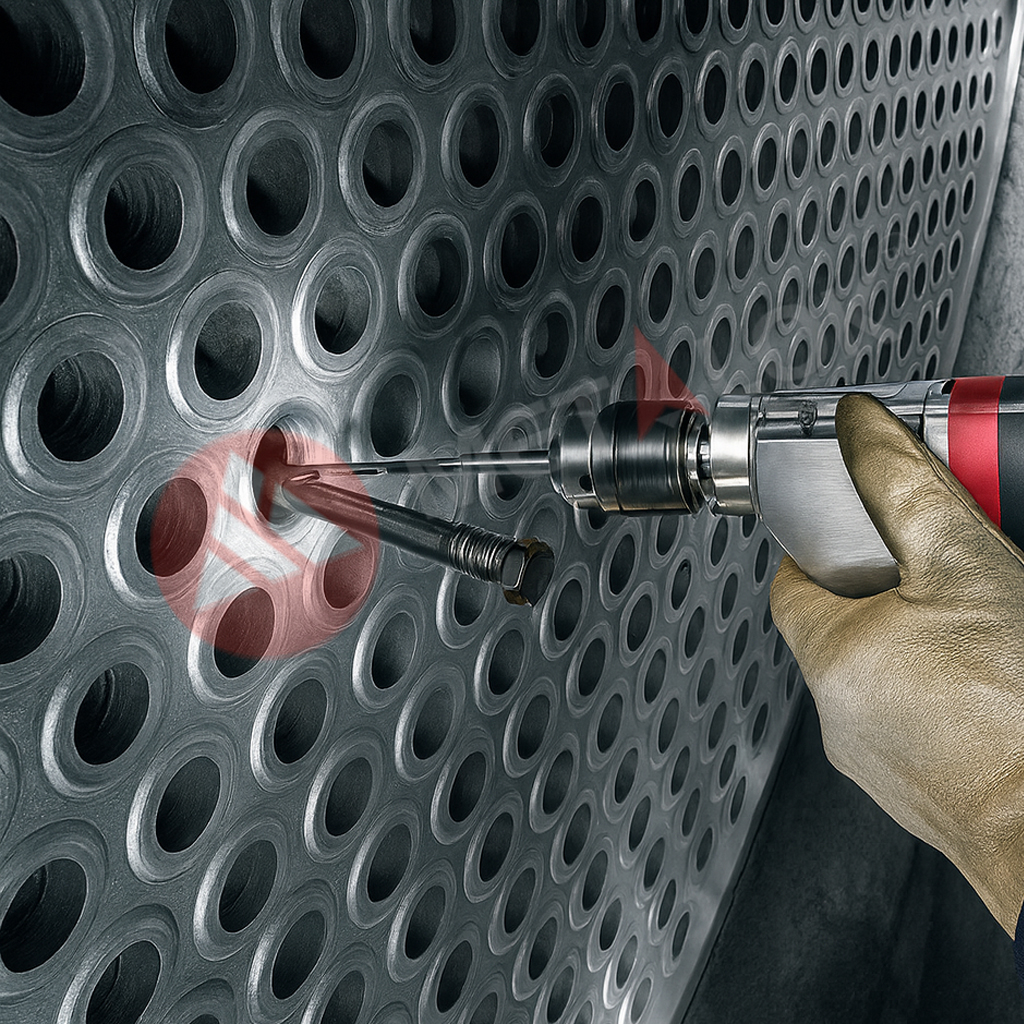

- Tube Removal: Safely remove damaged or worn tubes using mechanical or hydraulic extraction tools.

- Tube Sheet Preparation: Clean, ream, and inspect tube sheet holes to ensure a smooth and accurate fit.

- Tube Insertion: Insert new tubes with proper alignment and projection from the tube sheet.

- Tube Expansion: Expand tubes mechanically or hydraulically to achieve tight contact and sealing with the tube sheet.

- Tube Welding (if required): Perform TIG or orbital welding as per ASME/TEMA standards for high-pressure or critical applications.

- Testing & Inspection: Conduct hydrostatic or pneumatic pressure testing to verify tube integrity and leak tightness.

- Final Cleaning: Clean the entire exchanger internally and externally to remove debris or contaminants.

- Documentation & Handover: Record test results, material certifications, and inspection reports before handing over for operation.