Pop A Plug Removal

Products

- Fittings

- Instrumentation Valves

- Manifold Valves

- Double Block And Bleed Valves

- Industrial Valves

- Quick Release Couplings

- Air Headers

- Condensate Pots

- Flanges

- Flange To Tube Adaptors

- Thermowells

- Fastners

- Pipe Clamps

- Flush Rings

- Hose Fittings

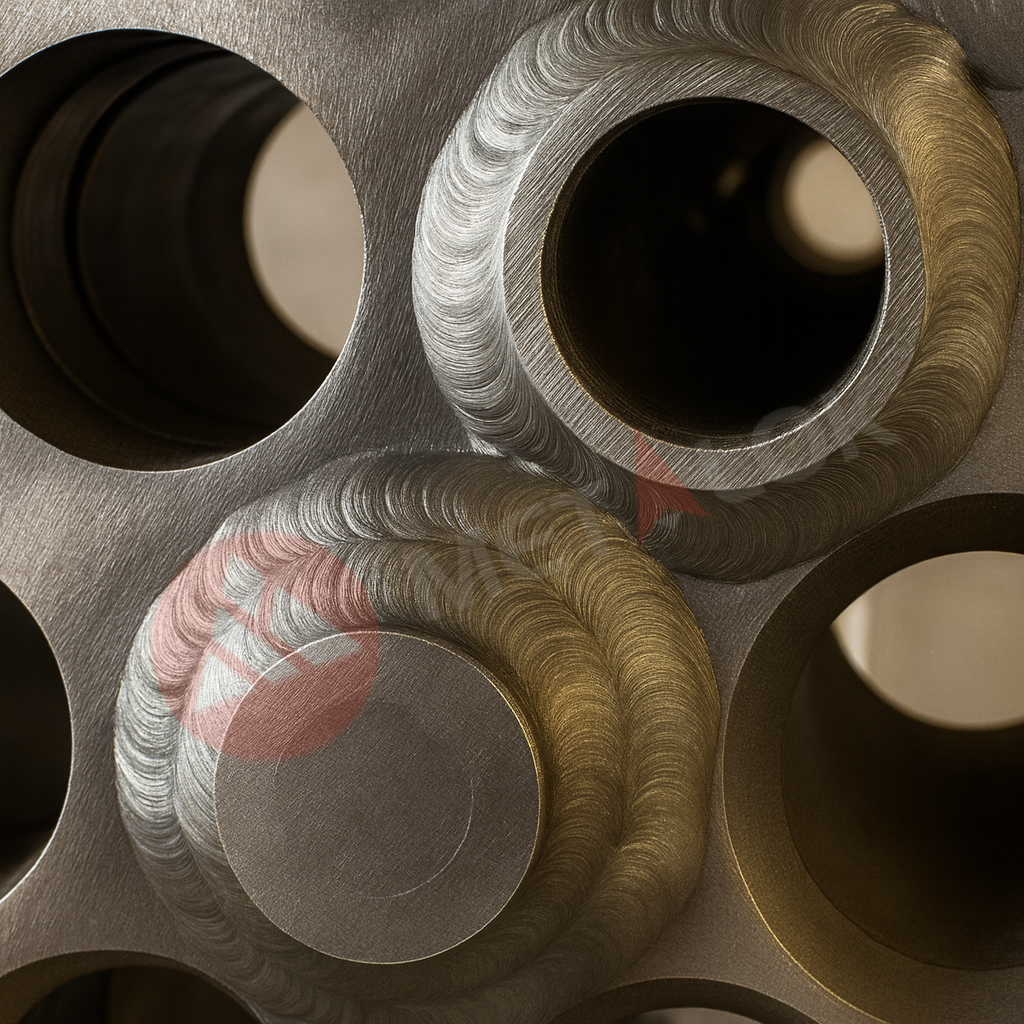

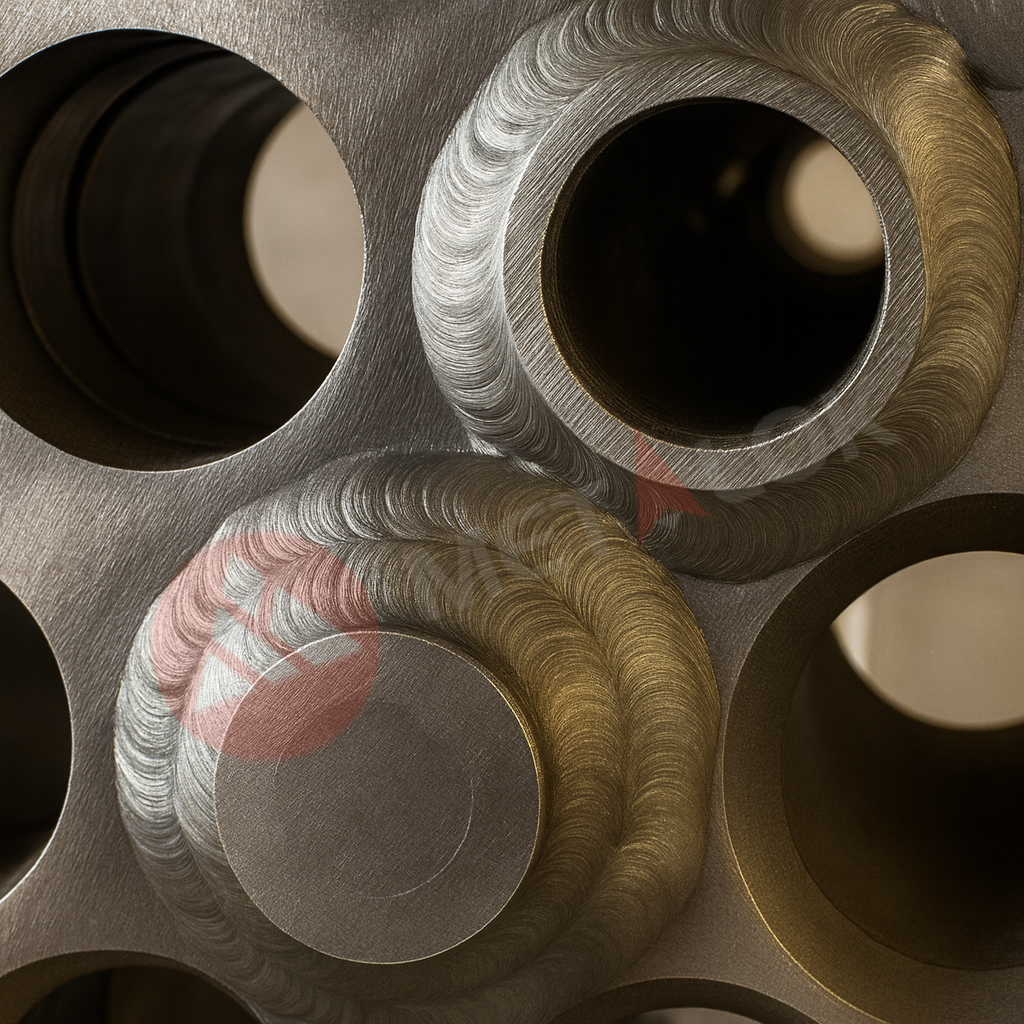

- Heat Exchanger Tube Plugs

- Heat Exchanger Ferrule Inserts

- Vent Plugs

- Header Unf Plugs

- Grease Fittings

- Pipes And Tubes

- Coils, Sheets & Plates

- Angle, Channels & Bars

- Tube Sheets

- Heavy Machined Components

-

Cleaning

-

Installation

-

Installation

-

Installation

Pop A Plug Removal

Mechanical fit plugs offer a safe, efficient, and reliable solution for sealing heat exchanger tubes and tube sheet leaks. Designed for durability, these plugs are resistant to thermal cycling and provide a helium-tight seal under demanding operating conditions.

Metalok Industries employs skilled and certified technicians equipped with advanced tools and precision instruments to ensure the highest standards of safety, performance, and system integrity during every installation or removal process.

It is essential that the installation and removal of mechanical fit plugs be carried out only by certified Metalok technicians with the appropriate training and equipment. This guarantees the safe handling and accurate sealing of both low-pressure plugs (up to 68.9 BarG) and high-pressure plugs (up to 483 BarG) in heat exchangers and related systems.

- Ensure the heat exchanger is fully depressurized, isolated, and drained before starting work.

- Verify safety permits (hot work, confined space, etc.) and wear proper PPE such as gloves, face shield, and goggles.

- Identify and mark the tubes containing Pop-A-Plugs to be removed.

- Clean the area around the plug to remove dirt, scale, or corrosion that may obstruct removal.

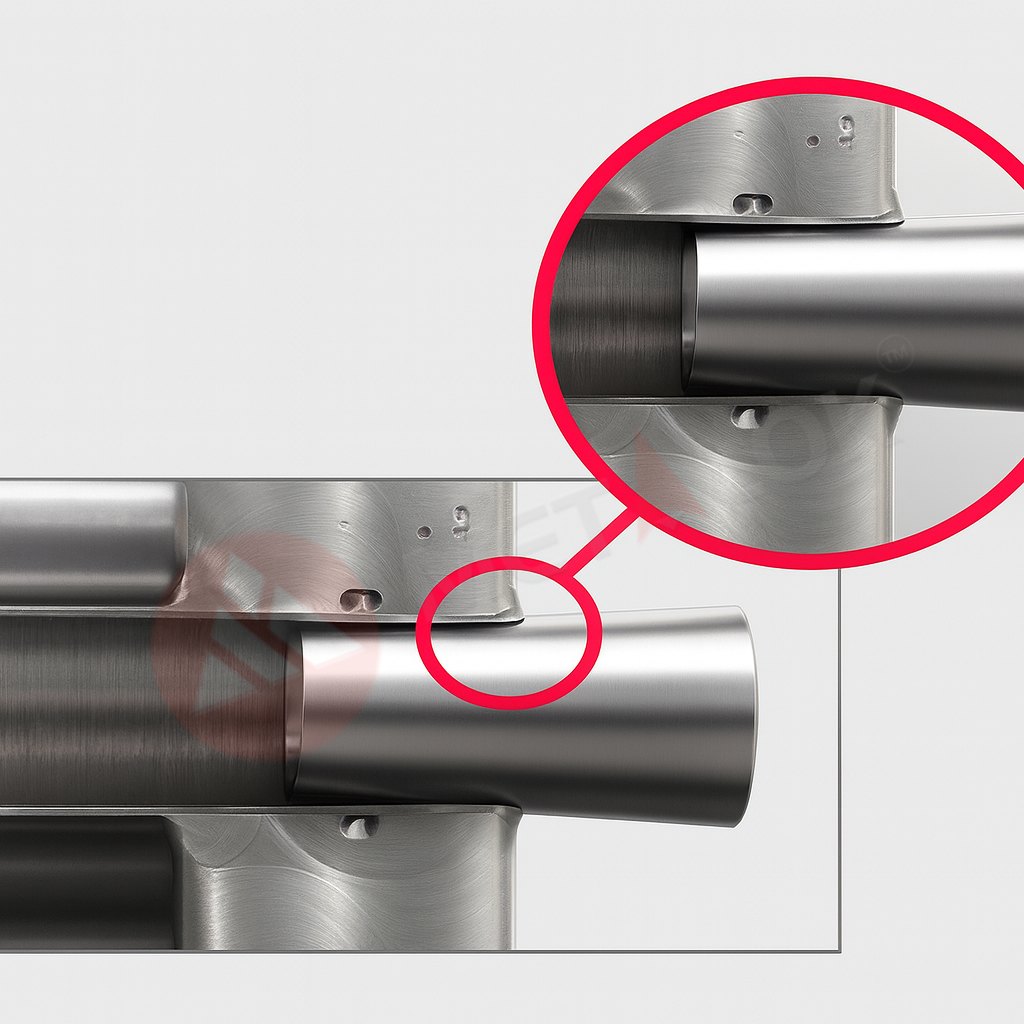

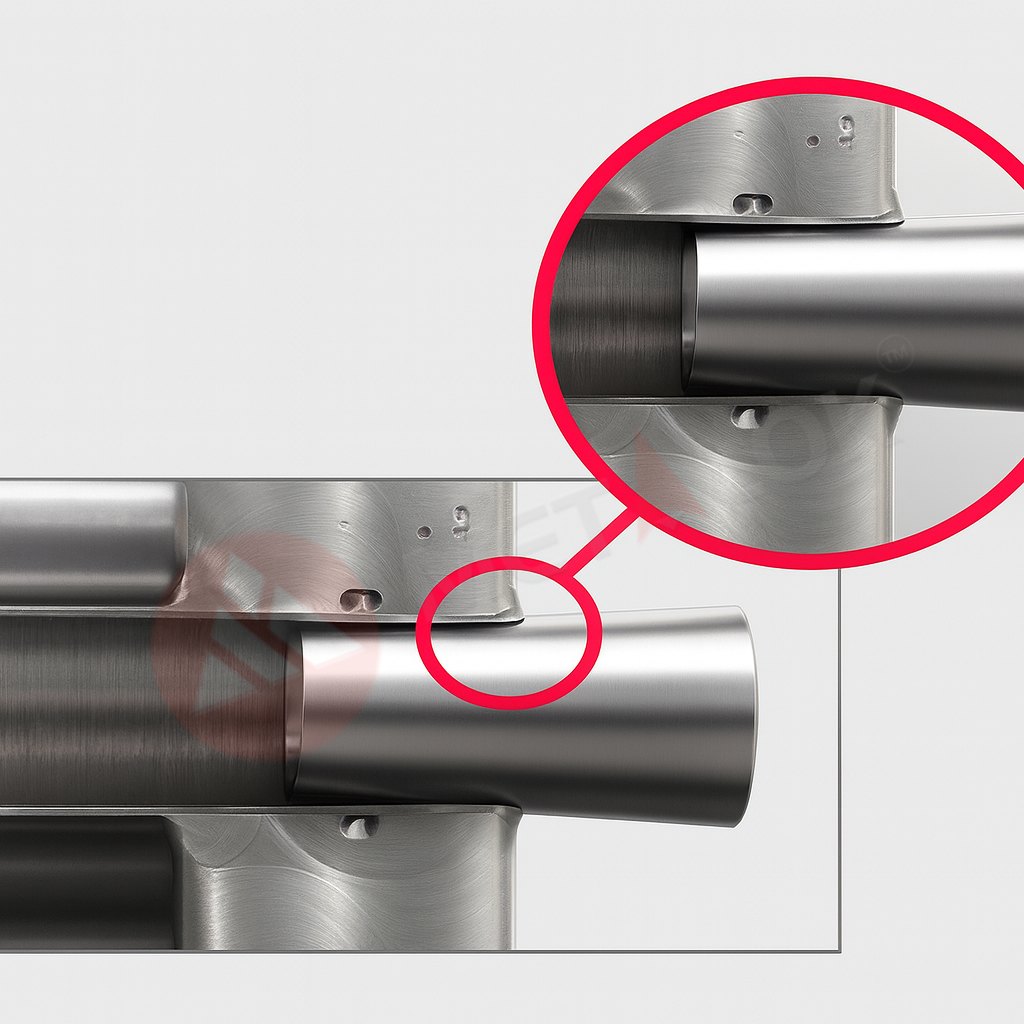

- Use the manufacturer’s recommended removal tool or extraction system designed specifically for Pop-A-Plugs.

- Align the removal tool accurately with the plug body to prevent damage to the tube or tube sheet.

- Apply steady and controlled force (mechanical or hydraulic) to extract the plug without jerking or twisting.

- Once removed, inspect the tube bore and tube sheet for any deformation, scratches, or remaining debris.

- Clean and prepare the tube for reinstallation of a new plug or repair, ensuring it’s free from any residue.

- Record the removed plug details (location, type, and condition) and dispose of the old plugs safely according to site procedures.